#modular automation

Explore tagged Tumblr posts

Text

Efficiency Redefined: Crabtree Smart-H Modular Automation Products

Explore Crabtree's Smart-H modular automation products, designed to optimize efficiency and streamline operations. From smart switches to integrated automation solutions, enhance your space with cutting-edge technology tailored to meet your needs. Discover the future of automation with Crabtree.

0 notes

Text

Smarter Surface Protection – PLC Automation in Autophoretic Coating Plants

In modern manufacturing, surface coating is not just cosmetic—it’s essential for durability, corrosion resistance, and performance. Autophoretic coating (also known as A-coating) has emerged as a water-based, eco-friendly alternative to electro-coating. When combined with PLC-based automation, it becomes a powerful, scalable solution for high-quality, uniform metal finishing.

Because let’s face it—metal without proper protection is like a knight without armour. In today’s industrial world, that armour comes in the form of surface coating. And when it comes to smart, sustainable, and scalable coating, autophoretic coating is the unsung hero.

But wait, here’s where it gets exciting. Pair this eco-warrior coating with PLC automation, and what you get is nothing short of magic. At Messung Industrial Automation, we believe that the perfect coat is not just about shine—it's about smarts, speed, and sustainability.Let’s dive into the world where chemistry meets code, and surface protection meets the future.

What is Autophoretic Coating?

Autophoretic coating, also known as A-coating, is a process where metal parts are dipped in a reactive water-based solution. The result? A self-depositing layer forms on the surface, without any electric current. Unlike traditional methods that zap the surface with electricity, A-coating lets chemistry take the wheel.

Why Are Industries Making the Switch?

Industries are coating their bets on it because it avoids the need for heavy electric setups and provides uniform coverage even in complex geometries. Since it is water-based, it is also very environmentally friendly.

Where Is It Being Used?

From under-the-hood car parts to refrigerator frames, autophoretic coating is making waves in:

Automotive parts

Appliance components

Agricultural and construction machinery

General industrial structures

In an age where efficiency, sustainability, and performance go hand in hand, autophoretic coating emerges as a transformative solution. Its simplicity belies its power, ushering in a cleaner, smarter way to protect surfaces without compromising on quality or cost. As industries across the board continue to embrace greener practices, A-coating, powered by automation and intelligence, is painting the future—one seamless coat at a time.

Role of PLC in the Coating Plant

In the realm of autophoretic coating, precision isn't a luxury—it's a necessity, and that precision begins with the silent genius of automation: the Programmable Logic Controller (PLC). Think of the PLC as the central nervous system of your coating plant—connecting, communicating, and commanding every mechanical muscle with machines. Here is how PLCs turn a basic coating line into a harmonious dance of efficiency and intelligence.

Precision Process Automation

A modern autophoretic coating plant runs smoothly like a well-coordinated team, and the PLC (Programmable Logic Controller) is in charge. It doesn’t just control the machines—it helps everything work perfectly together. From:

Tank temperature

Solution pressure & pH levels

Cycle timing for each dip and rise

...every step is monitored and controlled by PLC automation.

Material Handling Magic

Using intelligent material handling controllers, our PLC guides parts through multiple stages:

Degreasing

Surface conditioning

Coating dip

Rinsing & curing

Like a choreographer directing a ballet of metal.

Circulation & Filtration Mastery

Good coating = Consistent flow. Our process controllers and PLC control systems manage:

Fluid circulation

Filtration cycles

Solution replacement timing

Synchronisation with Process Controllers

Through seamless synchronisation with motion control systems, everything moves with precision. No drips, no downtime.

In an industry where milliseconds matter and uniformity is sacred, PLC automation elevates the autophoretic coating plant from functional to phenomenal. It enables not just control, but clarity—ensuring that every part, every dip, and every process flows with intelligent intent.

NX-ERA JET PLC System Architecture

Our flagship—NX-ERA JET PLC—is a robust, real-time, and rugged automation genius. It’s compact, reliable, and battle-tested in industrial heat.

Talk the Talk: MODBUS & TCP/IP

Built-in PLC communication protocols like:

MODBUS TCP/IP

MODBUS RTU

Make it plug-and-play with SCADA and automation systems. Yes, it speaks fluent-machine.

Ethernet-Based Controllers for High-Speed Sync

Using Ethernet-based controllers, data flows like molten metal. Zero lag, maximum productivity.

HMI with PLC Controllers

With user-friendly HMIs with PLC controllers, even a non-techie can operate complex coating sequences. Tap, drag, drop—and coat!

From seamless communication to intuitive control, the NX-ERA JET PLC is more than just a controller—it's the central nervous system of your autophoretic coating plant. With its advanced architecture, lightning-fast data sync, and plug-and-play compatibility, it transforms complexity into clarity. Whether you're scaling up or starting smart, this system offers the flexibility, durability, and intelligence your operations demand.In a world where precision meets pressure, the NX-ERA JET PLC ensures your plant doesn’t just perform—it excels.

Advanced PLC Automation for Smart Manufacturing

In the age of Industry 4.0, surface coating is no longer just about chemistry—it's about intelligence, precision, and adaptability. That’s where advanced PLC automation steps in as the invisible powerhouse behind your plant’s performance. Whether you're scaling up operations or streamlining a compact facility, smart automation is the lever that elevates your process from ordinary to outstanding.

Let’s uncover how Messung’s cutting-edge PLC technology is revolutionising autophoretic coating plants with flexible, responsive, and future-ready control systems.

Modular, Compact & Ready to Go - Whether it’s a big plant or a small-scale setup, our Modular PLC, Compact PLC, and Smart PLC configurations give you tailor-made flexibility.

Motion Control with Millisecond Precision - Our motion control systems enable synchronised movement, avoiding delays or overlaps in the coating sequence.

Material Handling - Our embedded material handling controllers do the heavy lifting—literally—without breaking a sweat.

This isn't just automation. This is smart automation that thinks ahead, moves with purpose, and adapts to demand. With Messung’s PLC-powered intelligence, your coating plant doesn’t just run—it evolves.

Because in the world of advanced manufacturing, it’s not just about staying ahead—it's about setting the pace.

Smart. Sustainable. Secure: The Evolution of PLC Automation in Coating Plants

In the era of Industry 4.0, coating plants need more than just control—they need intelligence, integration, and intention. Here’s how Messung’s PLC automation is redefining autophoretic coating systems:

Built for Harsh Industrial Realities – Our Industrial PLCs endure dust, moisture, heat, and vibration. Conformal-coated PLCs protect against corrosive chemicals in A-coating zones and provide long-lasting performance in extreme environments.

Safety Meets Smarts - PLCs are integrated for emergency stops, controlled shutdowns, and real-time fault alerts with logs, making them smart, secure, and always in control.

Welcome to Industry 4.0-Based Controllers

PLC with IoT for remote monitoring and real-time plant access.

MQTT-based PLCs for cloud-friendly, lightweight data communication.

Full PLC system integration with BMS, SCADA & more—ensuring a harmonious automation ecosystem.

Green Gains: Eco-Friendly A-Coating Automation

Water-based chemistry reduces VOCs and emissions.

Smart PLCs optimize dosing & disposal—minimising waste, maximising results.

Cleaner air, cleaner conscience, smarter coatings.

With Messung’s intelligent PLC, you don’t just automate—you evolve. Sustainable, scalable, and secure—this is the new face of PLC-based automation solutions in A-coating.

Business Benefits of PLC-Based Automation Solutions

In today’s hyper-competitive manufacturing world, success isn’t just about innovation—it’s about consistency, efficiency, and scalability. This is where PLC-based automation doesn’t just support your coating process—it transforms it. Let’s explore how Messung’s smart automation systems turn operational goals into tangible business advantages.

Uniformity Every Time - When every product must meet the same high standard, there’s no room for guesswork. Thanks to PLC control systems, your coating process is even, repeatable, and of high quality.

Never any Downtime - Time is money, and downtime is a thief. With real-time monitoring and intelligent automation controllers, potential issues are detected and resolved before they affect production. Fewer breakdowns. More uptime. Happier bottom line.

Easy to Maintain & Scale - Growth shouldn’t be a gamble. With built-in PLC maintenance alerts, you get proactive notifications that prevent surprises. Want to expand operations? Simply plug and play with modular I/O modules. You’re ready for tomorrow—today.

In essence, PLC automation is not just a control system—it’s a business strategy. It safeguards quality, boosts efficiency, and equips your coating plant with the agility to evolve. Because when your process is smart, your performance is unstoppable.

Conclusion: The Final Coat

A surface is only as strong as the system behind it. In the era of smart manufacturing, Messung’s PLC automation solutions empower autophoretic coating plants with unmatched precision, efficiency, and sustainability. From real-time monitoring and advanced PLC control systems to seamless IoT integration and predictive maintenance, our technology ensures optimal surface protection with minimal waste. Whether it’s modular PLCs, industrial automation controllers, or motion control systems, Messung delivers the complete package. So why let inefficiencies corrode your bottom line? Upgrade your coat. Upgrade your process. Upgrade with Messung PLCs—where intelligent automation meets perfect protection.

FAQs

How does PLC contribute to energy efficiency in coating plants?

By optimizing process timings, reducing idle machine hours, and enabling intelligent power management, PLCs help cut down energy consumption and operational costs.

Can PLC automation reduce coating defects?

Absolutely. With real-time monitoring, precision control, and error alerts, PLC automation ensures consistent quality.

How easy is it to integrate Messung PLCs in existing lines?

Very! Our modular PLC systems and versatile PLC communication protocols like MODBUS and TCP/IP allow seamless integration.

Are conformal-coated PLCs necessary?

Yes, especially in chemically aggressive environments like coating plants. They extend the life and reliability of your Programmable Logic Controller.

What industries benefit most from PLC with IoT?

Automotive, general manufacturing, and any industry embracing Industry 4.0-based controllers and smart factory setups.

#Autophoretic coating#Messung Industrial Automation#PLC automation#Programmable Logic Controller (PLC)#material handling controllers#motion control systems#NX-ERA JET PLC#HMI with PLC Controllers#advanced PLC automation#Modular PLC#Compact PLC#Smart PLC#Industrial PLCs#Smart PLCs#PLC-based automation solutions#PLC control systems#PLC automation solutions#IoT integration#industrial automation controllers#Industry 4.0-based controllers

0 notes

Text

Smart Public Toilets in India: Automated, Prefabricated & Plug-and-Play Sanitation Solutions by Nest-In

India’s growing urbanization and the urgent need for sustainable sanitation infrastructure call for smart, efficient, and scalable solutions. Nest-In, a Tata Steel initiative, addresses this challenge with prefabricated sanitation solutions in India that are not only cost-effective but also technologically advanced. One such innovation is the EzyNest – a new-age plug-and-play sanitation solution designed to redefine public hygiene and infrastructure efficiency.

Meeting the Urban Sanitation Challenge with Innovation

Sanitation remains a crucial public health concern, especially in densely populated urban and semi-urban areas. Traditional construction methods often fail to keep up with the speed and hygiene requirements of fast-developing regions. This is where Smart Public Toilets come into play—offering cleaner, faster-to-install, and more sustainable alternatives.

Nest-In’s EzyNest modules are designed to cater to this exact need. They are fully built off-site using modular construction methods and transported for immediate installation. These automated modular toilets minimize the need for on-site labor, reduce time, and enhance hygiene by integrating technology-led features.

What Makes EzyNest Stand Out?

EzyNest isn’t just another prefabricated toilet; it’s a smart blend of design, technology, and user-centric features. Here’s what makes it ideal for urban and rural deployment:

Plug-and-Play Installation: EzyNest comes in pre-finished modules that can be installed in a matter of hours, not days—perfect for emergency or remote-area sanitation needs.

Durability and Sustainability: Made with corrosion-resistant steel and high-quality internal fittings, EzyNest units are built to last in varied climatic conditions across India.

Smart Technology Integration: Features like occupancy indicators, water-saving sensors, solar panels, and remote monitoring capabilities make these Smart Public Toilets ideal for municipalities and corporate campuses.

Low Maintenance: Designed for easy cleaning and low upkeep, ensuring hygiene standards are maintained over the long term.

Scalable for Government and Corporate Needs

Whether it’s a Smart City project, Swachh Bharat Abhiyan initiative, or a CSR-driven sanitation program, prefabricated sanitation solutions in India like EzyNest offer a scalable, cost-efficient, and rapidly deployable infrastructure model.

Corporate campuses, highway rest stops, educational institutions, and construction sites can benefit greatly from Nest-In’s Automated Modular Toilets, as they require minimal civil work and can be relocated or expanded with ease.

Aligning with National Goals and Global SDGs

Sanitation is a major pillar of India’s urban and rural development plans. EzyNest supports the government’s objectives by providing eco-friendly, quickly deployable, and inclusive solutions that align with Sustainable Development Goals (SDGs), especially SDG 6 – Clean Water and Sanitation.

Additionally, features like accessible design for the differently-abled and gender-segregated cabins ensure inclusivity and universal usability.

Why Choose Nest-In’s Plug-and-Play Sanitation Solutions?

Backed by the legacy and quality assurance of Tata Steel

Fast deployment with minimal environmental disruption

Sustainable design with solar energy and smart water usage

Easily scalable for different needs—from villages to metros

Ideal for both public and private sector use

Conclusion

With rapid urbanization and increasing demand for hygienic public infrastructure, plug-and-play sanitation solutions like EzyNest by Nest-In are transforming the sanitation landscape in India. These smart public toilets represent a leap forward in how India can ensure access to safe, sustainable, and dignified sanitation for all.

If you're looking to implement cutting-edge automated modular toilets in your smart city, township, institution, or commercial project, Nest-In offers an unmatched combination of quality, speed, and innovation.

#prefabricated sanitation solutions in India#Smart Public Toilet#Automated Modular Toilets#plug-and-play sanitation solutions

0 notes

Text

The Bently Nevada 3500 System Machinery Condition Monitor Modular from Auto2mation is a trusted solution for continuous monitoring of rotating equipment. Designed for high performance and reliability, this modular system helps detect potential machine issues early, reducing unplanned downtime and maintenance costs. It offers advanced vibration analysis, flexible configuration, and seamless integration with plant systems. Ideal for industries like oil & gas, power, and manufacturing, the 3500 system ensures safer operations and longer equipment life. With real-time monitoring and data collection, it supports smarter decision-making and improved machinery health. Choose Auto2mation for dependable machinery protection solutions.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#Bently Nevada#Monitor Modular#Electronic components

0 notes

Text

Discover the Best Interior Designers in Bhubaneswar with Ambikraft

As someone who recently went through the exciting (and sometimes overwhelming) journey of designing my home, I want to share my personal experience and insights. If you're searching for the best interior designers in Bhubaneswar, you’ve landed in the right place. With Ambikraft by my side, transforming my space into a stylish and functional haven was not just easy but a truly enjoyable process. Here's everything you need to know if you're planning to upgrade your home or office in Bhubaneswar.

🛋️ Why I Chose Ambikraft for My Interiors

Personalized Design Approach From the first meeting, the team at Ambikraft focused on my tastes, needs, and lifestyle. They didn’t push a standard design but built something that felt uniquely me.

Modern Modular Design Expertise Whether it was the bedroom, living space, or kitchen, Ambikraft’s expertise in modular interior design in Bhubaneswar stood out. Everything was clean, compact, and clever—maximizing my space and style.

One-Stop Interior Solution From planning to execution, they handled everything—saving me from chasing multiple vendors or worrying about timelines.

🍽️ The Best Modular Kitchen in Bhubaneswar? I Found It.

Smart Layouts with Elegant Finishes I didn’t just want a kitchen; I wanted a kitchen that makes cooking joyful. Ambikraft’s designs struck the perfect balance between function and beauty.

Top-Notch Quality and Materials Their use of durable and premium materials ensures my modular kitchen looks brand-new even after months of use.

Customized Storage Solutions Every drawer, cabinet, and shelf was tailored to my cooking habits. That’s what sets them apart from other modular kitchen manufacturers in Bhubaneswar.

🛠️ Why Modular Interior Design is the Future

Efficient Use of Space Modular designs, especially in compact apartments, make life so much easier. Every corner has a purpose.

Easy Maintenance & Upgrade With modular setups, it’s much simpler to clean, repair, or upgrade specific parts without dismantling everything.

Budget Flexibility You can scale your design up or down based on your budget. Ambikraft helped me create a plan that fit my wallet without sacrificing quality.

🏠 Why You Should Work With the Best Interior Designers in Bhubaneswar

Professional Project Management Timely delivery, clear communication, and regular updates made my renovation journey stress-free.

Access to Latest Trends & Tech From 3D visualizations to the latest lighting and furnishings, Ambikraft gave me a glimpse into the future of interior design.

Post-Installation Support Even after the work was done, they checked in to ensure everything met my expectations. That level of commitment is rare.

🔄 Final Thoughts

Working with Ambikraft was the best decision I made for my home. Whether you need complete home interiors or are looking for the best modular kitchen in Bhubaneswar, they’ve got you covered. Their dedication, creativity, and professionalism truly make them the best interior designers in Bhubaneswar.

If you're planning a makeover or starting fresh, visit Ambikraft and take the first step toward your dream space.

📅 Visit us today and experience ultimate relaxation! 📞 Phone: 8093086630 📧 Email: [email protected] 📍 Address: Plot no 803/3317, Mayfair Lagoon Rd, Jayadev Vihar, Bhubaneswar, Odisha 751013 🌐 Website: https://ambikraft.com/

#graphic design#best interior designers in bhubaneswar#modular interior design in bhubaneswar#home theatre system in bhubaneswar#home automation & Security service provider in odisha#tv unit design#modular kitchen in bhubaneswar

0 notes

Text

Automatic Industrial Tunnel Pasteurizers Market to Reach $1008.7 Million by 2035

The global Automatic Industrial Tunnel Pasteurizers market is on track for substantial growth, with projected revenue rising to $1008.7 million by 2035, up from $387.0 million in 2024. This reflects a compound annual growth rate (CAGR) of 9.1% over the forecast period from 2024 to 2035.

Detailed Analysis - https://datastringconsulting.com/industry-analysis/automatic-industrial-tunnel-pasteurizers-market-research-report

These pasteurizers play a crucial role in several sectors including food processing, beverage bottling, and pharmaceutical packaging. The market is set to benefit from rising consumer demand for safe, long-shelf-life products, alongside innovations in food processing technology and automation.

Competitive Landscape and Market Leaders

The Automatic Industrial Tunnel Pasteurizers industry is marked by intense competition and the presence of several globally recognized players. Leading companies driving innovation and market penetration include:

Alfa Laval

Tetra Pak

GEA Group

Krones AG

Shandong Jimeile Limited

KHS GmbH

JBT Corporation

PERACETTI

Primodan

Technibag

FBR-ELPO

REDA S.p.A.

With a strong focus on technological advancement, automation, and energy-efficient pasteurization processes, these companies are investing heavily in R&D to meet growing food safety regulations and operational efficiency demands.

Growth Drivers and Market Opportunities

Several key trends are shaping the future of the Automatic Industrial Tunnel Pasteurizers market:

Demand for Processed Foods: Increasing urbanization and changing dietary preferences are fueling the need for large-scale, reliable pasteurization solutions.

Technological Innovations: Developments in temperature control, automation, and modular design are enhancing productivity and energy efficiency.

Emphasis on Food Safety: Regulatory pressure and consumer expectations around hygiene and safety are pushing demand for advanced pasteurization technology.

Emerging Markets: Rapid industrialization and infrastructure investments in countries like China, India, Brazil, and Saudi Arabia offer major growth opportunities.

Strategic Partnerships: Collaborations among OEMs, integrators, and end users are creating new avenues for market penetration.

Regional Trends and Supply Chain Evolution

The North American and European markets currently dominate the global landscape due to their mature food processing industries and stringent food safety regulations. However, emerging markets in Asia-Pacific, South America, and the Middle East are becoming key focal points for expansion.

Despite facing challenges such as high installation and maintenance costs and a shortage of skilled labor, the overall ecosystem—from raw material sourcing and component manufacturing to assembly and end-use applications—is expected to become more agile and decentralized. Companies are expanding their operations and making strategic investments in Brazil, India, and Saudi Arabia to enhance supply chain efficiency and tap into new revenue pools.

About DataString Consulting

DataString Consulting is a trusted name in market intelligence, offering end-to-end research solutions across both B2C and B2B segments. With a leadership team boasting over 30 years of collective experience, the firm delivers actionable insights to support data-driven decisions.

From strategy consulting and competitive intelligence to opportunity assessment, DataString provides customized research services tailored to your unique business objectives. Monitoring more than 15 high-growth industries, their team of data experts and analysts ensures accurate, timely, and forward-looking insights.

#Industry Tags#Food Processing Equipment#Industrial Pasteurization#Tunnel Pasteurizers#Beverage Processing Equipment#Pharmaceutical Packaging Equipment#Market Research Tags#Market Forecast 2035#Industry Trends#Global Market Analysis#CAGR Growth#B2B Market Intelligence#Technology & Innovation Tags#Food Safety Technology#Automation in Food Industry#Energy Efficient Pasteurization#Smart Manufacturing#Modular Pasteurizer Design#Business Strategy Tags#Strategic Partnerships#Revenue Growth Opportunities#Emerging Market Expansion#Competitive Intelligence#R&D Investment Trends#Geographic Tags#North America Market#Europe Food Tech#Asia-Pacific Expansion#Middle East Industrial Growth#Latin America Food Processing

0 notes

Text

🔧 BI-TORQs Knife Gate Valves 🔧 Built for demanding applications like solids, slurries, wastewater, and more! 💧 Available in wafer/lug styles and cast-iron/stainless-steel bodies. Standard handwheel with options for pneumatic cylinders or electric actuators for precise control. Plus, we offer extensions, gears, and chain wheel operators to suit your needs. 👇 Contact Us for More Details👇 📧 [email protected] 📞 +91 9787878732 🌐 https://www.nayagi.in/bi-torq/

#KnifeGateValves#KnifeGate#Valves#GateValves#ValvePositionerSuppliers#IndustrialValves#EasyUpgrades#Automation#TechInnovation#Modularity#IndustrialSolutions#EngineeringExcellence#Pneumatics#IndustrialAutomation#BiTorq#mechanicalproducts#bengaluru#industrialtoolssuppliers#IndustrialDealers#NayagiIndustrialTechnologies

1 note

·

View note

Text

Crabtree Curtain Relay Switch ACWAA023 | Smart Home Automation | Havells

Automate your living space effortlessly with the Crabtree Curtain Relay Switch ACWAA023. Designed for smart home integration, this modular switch offers seamless control over curtains and blinds. Experience advanced convenience with reliable performance from Havells.

0 notes

Text

The Siemens SIMATIC S5 PS 7A/15A Modular Power Supply is a high-reliability power supply unit designed for Siemens SIMATIC S5 automation systems. It provides stable and regulated DC power to support the operation of S5 programmable logic controllers (PLCs) and associated modules. The power supply features a modular design, allowing for easy integration and expansion within the automation system. With a 7A output current capability and a 15A peak current, it ensures consistent performance even under high-load conditions. Built for industrial environments, the SIMATIC S5 PS 7A/15A offers robust protection against electrical faults and ensures dependable operation of automation processes.

0 notes

Text

Knife roller conveyor Manufacturer in Pune | India

Enhance safety and productivity with our advanced and innovative knife roller conveyor manufacturer in Pune, India with high-quality products which is easy to install, and economical. Knife roller conveyors offer an array of advantages setting them apart as the preferred choice for precision material transport.

#Knife Edge Conveyor Manufacturer Pune#Weighing Conveyor Manufacturer Pune#Flat Belt Conveyor Pune#Activated Roller Belt Conveyor Pune#Flexi Link Conveyor Manufacturer Pune#Modular Conveyor Manufacturer Pune#Automation#Assembly Techniques.

0 notes

Text

SINAMICS S120: The Drive Solution for Modern Industries

Today’s industrial landscape is characterized by speed; therefore, the ability to operate efficiently, precisely and adapt to changes are key elements necessary for success. This is where the SINAMICS S120 drive system by Siemens comes in with a revolutionary approach aimed at satisfying such needs. By means of its sophisticated functions and versatile structure, SINAMICS S120 is revolutionizing the way industries handle motion control and automation.

The SINAMICS S120 remains one of the dynamic drive systems in the industry which organizes to serve such applications considering that they may require high performance systems with respect to their management skills. The modular construction allows this machine to be used by various sectors ranging from automotive industry up to consumer electronics hence being an essential instrument for firms striving at improving their productivity.

Key Features of the SINAMICS S120

Modularity and Scalability: The modular design of SINAMICS S120 gives room for a personalized solution hence an ideal option for various applications whether it is single-axis or complex multi-axis systems. The drive system can scale according to your business progress in this flexibility thus eliminating the need for extensive reconfiguration driven by ever-changing demands.

Advanced Safety Functions: Integrated safety features are essential for industrial modern environments. The SINAMICS S120 contains extensive safety features that adhere to international rules and standards, safeguarding operators and machines while reducing downtime.

Precision Control: To ensure quality and efficiency, high precision must be achieved in motion control. Accurate and constant control of motion management, which SINAMICS S120 provides with excellence, allows for synchronized multi-axis movements important in such applications as robotics and CNC machining.

Energy Efficiency: The SINAMICS S120 helps reduce operational costs while minimizing environmental impact and offers energy-saving capabilities in an era where sustainability is key. Its intelligent energy management features help optimize power usage across various processes.

Applications of the SINAMICS S120

Diverse industries use the SINAMICS S120, confirming its versatility and effectiveness.

Automotive Manufacturing: The accuracy in the assembly lines has been confirmed, and product quality and speed of production have been enhanced.

Packaging Industry: Amplifies productivity of distributing networks accompanied by unified stirring management for smooth-going activities.

Robotics: The precision and flexibility required for intricate robotic uses is offered thus making sure of their accurate and repeatable movements.

Integration and Compatibility

What makes SINAMICS S120 cool is it can be integrated seamlessly into existing systems. Presently it is compatible with other Siemens automation products such as SIMATIC controllers and HMIs. In addition, its support of multiple communication protocols allows for easy integration in different industrial environments.

Conclusion

More than merely a drive mechanism, the SINAMICS S120 serves as a driver of innovation and efficiency in industrial automation. Due to its modularity, precision and energy efficiency, it is an excellent choice for organizations wishing to remain on top in competitive surroundings. The use of SINAMICS S120 by businesses can reveal new heights of productivity and sustainability.

#siemens automation products#siemens dealers in ahmedabad#sinamics s120#siemens servo drive s120#sinamics s120 modular high performance drives

0 notes

Text

Explore Innovative Modular Automation Products - Crabtree India

Discover Crabtree's Smart-H series, a range of cutting-edge modular automation products for enhanced efficiency and control. Elevate your automation experience with reliable solutions designed for seamless integration. Explore now!

#Connected Living#Smart Home Solutions#Automation Products#Crabtree India#Smart-H Series#Modular Automation

0 notes

Text

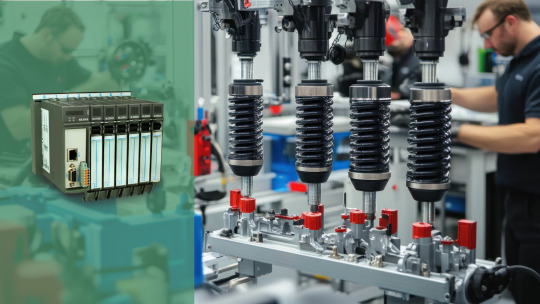

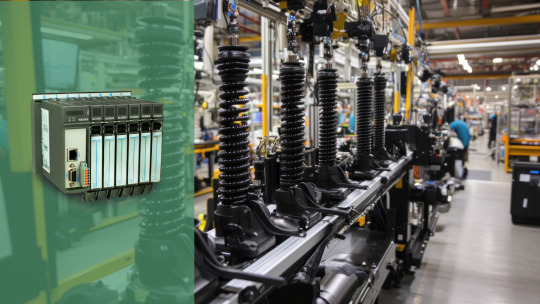

Precision Redefined – PLC-Controlled Shock Absorber Testing Machines

Precision – a word that keeps on getting thrown around often in the world of engineering. However, when it comes to shock absorber testing, precision isn’t a luxury—it’s survival. Every curve, every jolt, every rebound of a shock absorber must be captured, tested, and analysed to microscopic exactness. Gone are the days when manual testing could keep up.

The role of shock absorbers in today’s high-speed automotive innovation and precision engineering is to provide safety, comfort, and performance protection. But how can we make sure that these absorbers meet the high standards required by modern vehicles? This is where PLC automation becomes a useful tool.

The old-fashioned testing methods, which were cumbersome, unreliable, and laborious, have been replaced by PLC-based automation systems. Imagine a testing line with the capacity to think, adapt and respond in real time. The precision of Programmable Logic Controllers (PLCs) is not solely a promise, but rather adherence to standardised protocols.

How PLCs Enhance Shock Absorber Testing

There has been an evolution in the science of testing shock absorbers. Let’s understand how smart and compact PLCs can automate and optimise critical testing stages by providing consistency, control, and clarity.

Centralised Control with High Reliability

A robust industrial PLC is the foundation of our testing machines. The real-time control systems embedded in our automation design enable seamless functioning of all sensor, actuator, and motorised components.

Multiple sensors? Check.

Complex test sequences? Seamlessly handled.

From servo motion controllers managing high-speed vertical displacements to compact PLCs managing individual test stations, the formation is digital, deliberate, and dependable.

Real-Time Data Acquisition & Analysis

Here's where things get exciting. Tests on shock absorbers are more than just passing or failing. It's about quantifiable performance with our automation controllers:

Damping force curves

Displacement maps

Velocity and resistance profiles.

The data is gathered by high-resolution sensors and then processed through HMI with PLC controllers. The integration of this with databases is achieved through integrated PLC-based software, resulting in predictive maintenance and long-term performance insights

Feedback Loops for Adaptive Control

Ever wondered what would happen if the test differs? What would be the outcome? Well, with the use of real-time PLC communication protocols (like MODBUS and Ethernet/IP) and closed-loop control enable our systems to identify anomalies mid-test while enabling automatic correction.

Additionally, dynamic adjustment of actuator velocity in a system is possible when the response rate of the unit is slower than the tolerance. Or if temperatures spike? After a system shutdown, it sends an alert via the web server PLC and logs the fault. This requires more than just testing -- intelligent testing.

NX-ERA JET PLC System Architecture

Now let’s explore the engine room that fuels our innovation. The NX-ERA JET PLC, the foundation of our automated testing platform, undergoes a thorough architecture and connectivity analysis.

Core Hardware Components

With its compact size, modular design, and future scalability, the NX-ERA JET PLC is a formidable beast. It houses:

Simple servo systems designed for precise motion control

Energy-efficient motors can be powered by Variable Frequency Drives (VFDs)

HMI interfaces that enable the creation of visual dashboards and manual overrides

I/O modules for interfacing with third-party equipment.

Its modular design makes it suitable for both high-volume testing environments and small-batch production lines that use Micro PLCs or Mini PLCs

Communication & Connectivity

Connectivity should be a fundamental aspect of the entire setup, not an extra one.

Modbus PLC Interface is responsible for ensuring device-to-device communication

High-speed data relays are made possible with Ethernet-based controller systems

PLC with TCP/IP can be used for remote data logging and system control, as well as firmware updates

IoT-ready PLCs enable the integration of the testing machine with ERP, MES, and SCADA

Key Benefits of PLC-Controlled Testing Machines

Indeed, inefficient processes are not easily exploited in the fast-paced manufacturing industry. Your requirements include testing devices that don't blink even when pressured, systems that guarantee high quality, and technology that evolves as your business grows. Our PLC-based automation solutions are precisely in tune with that.

They offer:

Repeatability and Precision - One unit can be tested with ease and accuracy. But what about testing thousands with zero deviation? Our automation solutions that utilize PLCs accomplish this objective. You get:

Identical test cycles

Calibrated control parameters

Automated calibration routines

It implies improved quality control and enhanced audit accessibility.

High Throughput with Reliability - Traditional systems often require individuals to choose between speed and accuracy. Not here. The configurations of our NX-ERA JET PLC enable:

Sub-second test cycles

Parallel station control

Integrated logic and safety layers

All without compromising test integrity.

Reduced Manual Intervention - By utilizing HMI integration, and adaptive PLC programming, operators can not only monitor and but control:

Reduced human error

Faster changeovers

Safer work environment

Safety and Compliance – Safety is crucial for any industrial setup. With our smart PLCs, you can easily:

Emergency stop circuits

Real-time fault diagnostics

Layered safety logic

PLCs are designed to provide timely and effective alerts and shutdowns, complying with international standards such as ISO and CE.

Adaptable and Future-Ready - Different testing may be required for tomorrow's shock absorber. Good news: you won’t need a new machine.

Reprogram testing logic

Add new motion profiles

Update firmware via PLC with IoT

That’s the power of modular PLCs.

Whether you're chasing precision, throughput, or transformation, our PLC-controlled shock absorber testing machines deliver across the board. These benefits aren’t just technical specs—they’re business advantages, engineered to give you control, confidence, and a competitive edge.

Why Choose Messung’s Programmable Logic Controllers for Automation Solutions

Your choice of controller can determine your plant's success in a world propelled by data-driven decision-making, agility, and accuracy. We offer complete PLC-based automation solutions meant to grow with your demands rather than just supply PLCs. Our PLCs are not only intelligent but also necessary for the following reasons:

Smart and Connected PLCs - Our smart PLCs dynamically optimise by adjusting to handle changes. Embedded intelligence enables them to learn from repeated tests, predict component failures, and optimize actuator profiles automatically. Moreover, our edge-computing enabled PLCs help for quicker decisions by lowering cloud dependence.

HMI Integration for Better User Control - No more enigmatic command-line interfaces. With our smart PLCs, you get touchscreen HMIs, customised dashboards and real-time analytics displays.

Compact and Versatile PLC (Programmable Logic Controller) Options - Squeezed on space? You can get the complete power of a typical controller, without worrying about the size, with our compact PLC, micro PLC, and mini PLC range.

From intelligence that anticipates, to interfaces that simplify, to form factors that adapt—Messung’s PLC Programming range is designed not just to meet your automation goals, but to exceed them. Because when you choose Messung, you don’t just adopt automation; you embrace transformation.

Applications Beyond Shock Absorbers

Although shock absorber testing is where our PLC automation solutions show their power, that's just one section in our automation playbook. Beyond the same technology, fine-tuned for real-time control, precision, and adaptability, extends far. Messung's intelligent PLC solutions provide flexibility and value across a range of sectors, whether you are forming metal or transporting materials.

Let's explore how our PLC Control Systems have a range much outside the damping zone:

Motion Control Systems - Conveyor automation and actuator-driven systems all fall under our motion control solutions. Through synced servo motion controllers, we guarantee millisecond-level accuracy.

Machine Tool Controllers - Integrated with smart CNC tools, our machine tool controllers use feedback to adjust cutting speeds, minimise tool wear and even optimise material usage.

Advanced Automation – Through this end-to-end automation, sending raw material to finished parts, fully automated quality checks and centralized command via connected PLCs can easily become possible.

One shouldn't limit automation to just one purpose. Whether it is in high-speed assembly lines or precise machining at Messung, our PLC automation systems are flexible enough to meet the demands of many industries. Beyond shock absorbers, our solutions usher in intelligent manufacturing possibilities one motion at a time.

Conclusion

Accuracy is a standard, not only a specification. If you are still using obsolete testing configurations, it's time to change course. Designed to bring not just performance but also purpose to your production floor, Messung's PLC-controlled shock absorber testing equipment helps you to achieve this.

Testing has to be quick, adaptable, and flawless, whether you are creating luxury cars or robust trucks. That is precisely what Messung's PLC control systems promise—and deliver.

We do not just automate; we elevate, from servo-tight control to smart data acquisition, from seamless integration to Industry 4.0-based controllers.

At Messung, accuracy is not just redefined. It has changed everything. Hence, go for it. Redefine accuracy. One test at a time!

FAQs

What makes Messung’s PLC Control Systems ideal for shock absorber testing?

Messung’s PLCs (Programmable Logic Controller) offer centralised control, real-time data capture, adaptive feedback loops, and ensure peak accuracy and speed.

Can Messung’s PLC Programming integrate with existing equipment?

Yes. With protocols like MODBUS, TCP/IP, and Ethernet-based controllers, our PLCs are designed for easy retrofitting and compatibility.

How do PLC Control Systems improve the testing process?

PLCs provide real-time emergency stop functionality, error detection, and ensure the equipment runs within safe operational parameters.

Do you offer remote access features?

Absolutely. With web server PLC (Programmable Logic Controller) capabilities and HMI with PLC controllers, you can monitor and manage testing remotely.

Is your PLC solution scalable?

Yes. With modular PLCs and IoT-ready systems, you can scale your setup to match your growth.

#PLC control systems#Programmable Logic Controllers (PLC).#Messung Industrial Automation#PLC automation systems#Smart PLC control#PLC-based AHU control system#modular PLC#Energy management systems#IEC 61131 based PLCs#compact PLC#IEC 61131-3 standard PLC Control Systems#MODBUS RTU#Modbus TCP#NX-ERA JET#PLC for energy systems#IEC 61131-3 compliant PLCs#modular PLCs#HMI with PLC controller#smart automation systems#programmable logic controller#smart PLCs#Modular PLCs

0 notes

Text

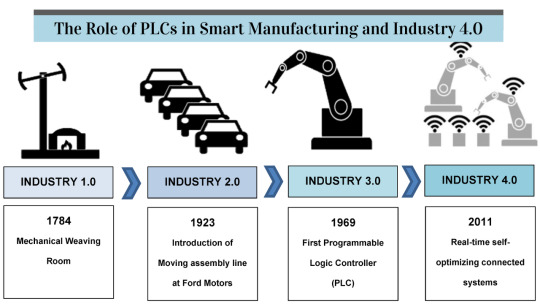

The Role of PLCs in Smart Manufacturing and Industry 4.0

Programmable Logic Controllers (PLCs) play a crucial role in the evolution of smart manufacturing and the implementation of Industry 4.0 principles. These advanced automation technologies are transforming traditional manufacturing processes into more connected, efficient, and intelligent systems.

🌐Website :- https://asteamtechno.com

👉Contact us :- +91 95372 40404

📧Email :- [email protected]

#automation#trending#tumblr trends#viral#trendingnow#bestdeals#allen bradley#rockwell automation#plc#viralpost#industry4.0#technology#companies#construction#manufacturing#modular plc

1 note

·

View note

Text

Event-Driven Design Demystified: Concepts and Examples

🚀 Discover how this cutting-edge architecture transforms software systems with real-world examples. From e-commerce efficiency to smart home automation, learn how to create responsive and scalable applications #EventDrivenDesign #SoftwareArchitecture

In the world of software architecture, event-driven design has emerged as a powerful paradigm that allows systems to react and respond to events in a flexible and efficient manner. Whether you’re building applications, microservices, or even IoT devices, understanding event-driven design can lead to more scalable, responsive, and adaptable systems. In this article, we’ll delve into the core…

View On WordPress

#Asynchronous Communication#Decoupling Components#E-commerce Order Processing#Event Broker Paradigm#Event Sources and Consumers#Event-driven architecture#Event-Driven Examples#Event-Driven Paradigm#Event-Triggered Workflows#Microservices and Events#Middleware in Event-Driven Design#Modular Development#Reactive Systems#Real-Time Responsiveness#Scalable Software Systems#Smart Home Automation#Social Media Notifications#Software Design Patterns#System Event Handling#User Experience Enhancement

1 note

·

View note

Text

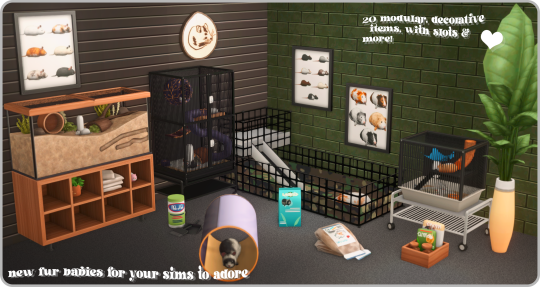

as anyone who knows me will know, my house is a zoo i am a sucker for small rodents, especially guinea pigs and hamsters. last year for my 17th birthday i shared these deco guinea pigs, so this year today, for my 18th, have the natural progression of that post: a 4t2 conversion of @kaisosims' rodents pack! 20 new, modular, decorative fur-baby items & accessories for your sims to adore 🥰

everything that could have fitted slots has slots; the hamster shelf, notably, has a grand total of 15! all of the cages are stackable, i.e.: you can put the animals (which are purely deco) in them, then stack them on top of any other surface--the given ones, or a counter, study table, etc.! more info can be found under the cut 👇

this set was originally supposed to be my... wow... 1000 followers and 17th birthday gift. but back then my cc skills honestly kinda sucked and the slots + transparency drove me to insanity. over a year, 1500 more followers, and a mental crisis later, here we are, with the final product of over 30 hours of hard work! 👏 in any case, thank you all so much for 2500 followers!

tysm to @skittlesplays for suggesting this set in the first place btw, you know me so well anna!! if you'd like to see my other, mechtasims pet set, which i converted in her honour, check out my 1000 followers gift weekend starting here.

DOWNLOAD: SFS | MF 🐹

credits go to @kaisosims for the original ts4 meshes & textures, they are so adorable! and of course to all of you, for sticking with me through another birthday 💖

DESCRIPTION

Originally by Kaisosims for TS4. Converted to The Sims 2 by nonsensical-pixels.

THINGS TO NOTE

Pretty much everything that can have a slot, has a slot!

All cages can be placed on other surfaces, like tables, counters, etc.; if you want to place an animal inside of them, do that first, THEN place them on the surface.

Everything is decorative; nothing is functional… yet.

Art pieces are in the Paintings category, surfaces like the Cage Stand are in Surfaces -> Misc, and everything else is in General -> Pets.

You may note that some items have drastically different polycounts from the TS4 originals; this is because TS4 automates the appearance of backfaces, but TS2 doesn't recognise them, so I had to add my own.

ITEMS INCLUDED

Art (28 polys) Cage Stand (398 polys) Cleaning Supplies (424 polys) Ferret (682 polys) Food (100 polys) Guinea Pig (484 polys) Guinea Pig Enclosure (4356 polys) Guinea Pig Enclosure Top (1008 polys) Hamster (520 polys) Hamster Cage (1758 polys) Hamster Table (308 polys) Rat (456 polys) Rat Cage (2140 polys) Small Cage (988 polys) Substrate (144 polys) Treats (1876 polys) Tube (640 polys) Wood Wall Art (380 polys) Zoom Pet (341 polys)

20 items total. Collection file included for added convenience!

much love from my lil piggies: bethany, ivory, emily, and alex!! they're getting new cages for my birthday, just like my sims' piggies 🐽

once again, thank you guys all so much for the support! i wish i could've added more to this gift but i guess this weekend's content will be compensation... 👀 if there are any issues that you find with this set, please don't be afraid to let me know! otherwise, i'll see you in the next one. happy simming, and when you download this, do keep in mind,

Love, ~ Ky 💓

#sims 2 download#the sims 2 cc#ts2cc#s2cc#sims 2 cc#the sims 2#sims 2#4t2#4t2 conversion#4t2 buy#suggestions#sims 2 suggestions#happy birthday to myself#<3 <3 <3

2K notes

·

View notes